We use our process knowledge and in-depth expertise to find the perfect solution for our customers. Through thermal testing, we guarantee the performance of our heat sinks and thus confirm our simulation results. In addition to thermal testing, we also validate pressure loss and water distribution in water-cooled heat sinks.

When validating heat sinks, we check the performance and quality standards of our customers’ equipment. In doing so, we ensure that all tested heat sinks comply with the specifications for the respective application.

When validating the heat sinks, real conditions are mapped and the results from the thermal simulation (CFD simulation with SolidWorks) are checked. This simulation and validation procedure rapidly determines whether and which development loops are still necessary before the product can go into series production.

![[Translate to English:] IGBT Prüfstand](/fileadmin/_processed_/6/3/csm_IGBT_Pruefstand_6758ccfbac.jpg)

IGBT Test Bench (Insulated Gate Bipolar Transistor) for Characterization of Air Coolers and Water Heat Sinks

We perform the thermal characterization of heat sinks using the IGBT test bench. The thermal path is disspated from the IGBT via the interface material, the heat sink and the cooling medium. In this way, we provide our customers with a thermal model for simulating various load cases.

The testing service is carried out by our experienced engineers. They work closely with our customers and ensure user-specific product characterization.

![[Translate to English:] Luftkühler](/fileadmin/_processed_/d/b/csm_Luftkuehler_05507a6ba9.jpg)

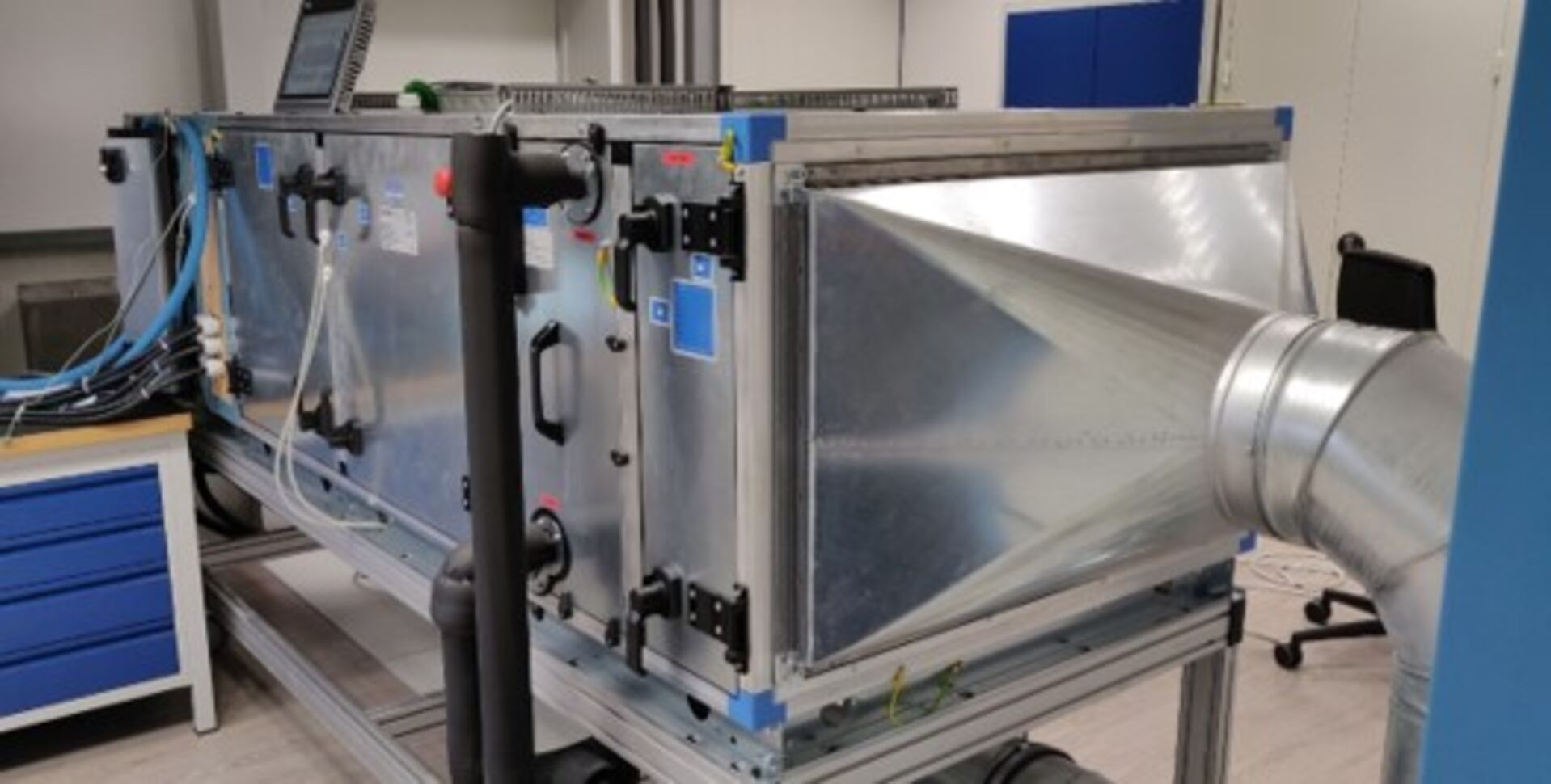

Air Cooler Test Bench for Heat Sinks

The flow channel test rig developed at Miba Cooling offers the possibility of providing conditioned volume flows in the 100 to 2000 m³/h range in order to determine the thermal behavior and pressure loss of air-cooled heat sinks.

The validation of heat sinks is the most important element of component development in high-performance electronics. With our expertise, we accompany our customers from the simulation of their application, through mechanical testing (e.g. pressure testing, flatness measurement, bursting tests) to thermal validation.

In this process, the optimum dimensions of the heat sink, the ideal flow field and the thermal behavior are determined. We carry out the tests with our customers' power electronics.

Serves to aid documentation and development results.

Prevent or minimize quality risks before series production or manufacture.

Identifies potential for improvement before series production.

We would be pleased to advise you.

We would be happy to advise you.

Our test benches are specially built for our customers' applications, so we guarantee our customers

With our test benches, we simulate different load cases, validate the performance of the heat sinks, and find the perfect solution for our customers.