The demands placed on heat sinks in a wide variety of industries, in particular the energy and industrial sectors, are high. They need to be able to deliver perfect performance even in the most challenging situations. The quality of heat sinks influences the entire function and service life of power electronics components.

Regular heat sinks are often not sufficient in certain industries and applications. That is where high performance heat sinks come in.

Below we discuss everything you need to know about this topic.

They are used for rapid heat removal to:

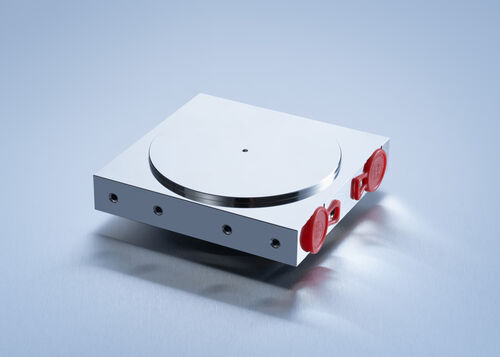

In contrast to regular versions, they can cool electronics with higher power density. This includes vacuum-soldered water cooled heat sinks.

These are very flexible in terms of design, in particular with regard to the internal cooling structure. Tailored cooling channels are precisely machined into aluminum plates. This means it is possible to produce optimized cooling plates with improved performance. They can then reach the areas where the highest cooling capacity is required.

The electronic components that are being cooled are very expensive. Outage would result in additional costs for various reasons:

High performance heat sinks have high cooling capacity to prevent such outages. That is why they are also suitable for high thermal performance.

This requires maximum reliability that cannot be provided by regular heat sinks.

High performance heat sinks must always be adaptable to meet specific customer requirements. This means that various technical requirements need to be met:

Once you have chosen the right product, the investment is worth it over the long term. You benefit from a longer machine life, less downtime and lower costs.

Miba Cooling creates a thermal, hydraulic and mechanical simulation based on your requirements. This will demonstrate whether the Miba high performance heat sink delivers the required performance. Would you like to find out more?

Contact us.