The Latest Technologies for Extreme Conditions

Miba Cooling is constantly working on the development of ever newer technologies. The aim is for the latest generation of semiconductors to deliver top efficiency even in extreme situations. Water cooled heat sinks in industry ensure the function and service life of the components in power electronics:

Water cooled heat sinks are a cost-effective solution in every industry due to the use of standard profiles

Our products ensure operational reliability over their entire service life of up to 20 years.

The latest generation of semiconductors ensures full functionality even in extreme conditions.

Contact us now.

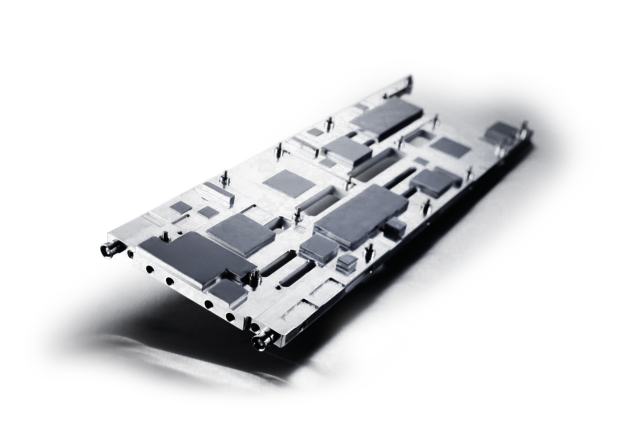

KW series

The KW series is a modular cooling plate series. It was developed to meet the requirements of a cost-effective and powerful liquid-cooled solution. It is therefore suitable for a wide range of standardized high performance IGBT configurations. It can also be used as a water cooled heat sink in many industries.

The solution comprises a main profile and two end caps, which ensure the required flow of water. There are various main profiles available. These are used depending on the required flow of water, the cooling requirements and the required positioning of the modules.

When this series is used, they should never be positioned above the end caps.

KS series

The KS series extends the options of the KW series. This series is manufactured from existing standard profiles. The connectors and I/O ports can be customized and configured to suit various industries. This makes it possible to achieve the thermal transfer rate specified for the required water flow.

This provides maximum flexibility in the configuration of this water cooled heat sink:

L/KLD/KP series

Some industries require a water cooled heat sink with a pipe material other than aluminum. Various solutions are available for this purpose with pre-shaped copper or stainless steel pipes.

Precision tube bending allows a virtually unlimited number of configurations for optimal thermal performance. There are various methods available. These include:

Both ensure optimal metallic contact and do not require an additional adhesive bond.

Application temperature profile from minus 40 °C to plus 120 °C (including on rail vehicles)

Regulates temperatures and prevents failures

From a high frequency to a low frequency of load changes during the operating cycle (for example in rail vehicles and traction converters)

Contact us now.

Vacuum-brazed heat sinks are the better alternative to Friction Stir Welding for certain applications.

You can read why this is the case in our blog article:

Vacuum-soldered heat sinks are flexible and enable optimized cooling plates with maximum performance.

Mehr dazu in unserem Blogartikel: How vacuum-brazed cold plates reduce costs and extend service life

The KW series is suitable for meeting the requirements of a cost-effective and powerful liquid-cooled solution.

For water cooled heat sinks in industries that require a pipe material other than aluminum, there are various solutions available featuring pre-shaped copper or stainless steel tubes.

Download