Efficient battery cooling is the key to long-lasting, high-performance battery systems in trains, agricultural machinery, trucks, buses, and stationary energy storage systems. Miba Cooling offers customized cooling solutions that guarantee maximum performance, reliability, and sustainability.

Our vacuum-brazed heat sinks ensure even cooling and prevent hot spots – for maximum efficiency of your battery cooling.

Thanks to their integrated structural strength, our solutions reduce system weight and increase the service life of battery cells – ideal for mobile and stationary applications.

Our battery cooling system is CO₂-reduced and manufactured with a high proportion of recycled materials – a strong contribution to sustainable mobility and energy storage.

Contact us now!

![[Translate to English:] Vacuum brazed heat sink](/fileadmin/_processed_/3/a/csm_BF7I6064_214ea27a9f.jpg)

Our vacuum-brazed heat sinks are specially designed for cooling high-capacity battery cells such as LTO, NMC, and LFP. These cooling technologies are tailor-made for industrial energy storage systems and mobile applications such as traction systems, buses, and construction machinery.

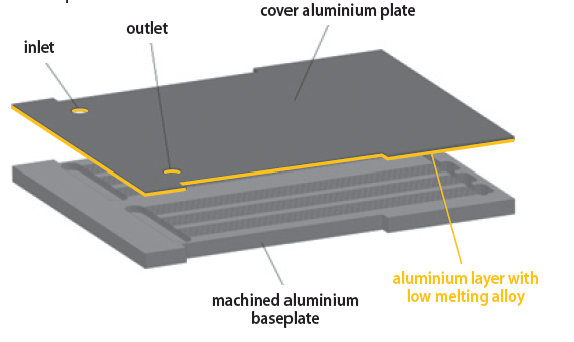

The heat sinks for battery cooling are manufactured using a vacuum brazing process. This involves placing a cover plate on a precision-machined or deep-drawn base plate and heating it in a vacuum brazing furnace at 580–600 °C.

A thin, rolled aluminum layer with a slightly lower melting point melts during this process, ensuring an extremely reliable, strong bond between the two components.

We offer two manufacturing options:

Our battery cooling solutions are used successfully in a wide range of demanding industries:

Contact us now!

CFD-optimized channels ensure uniform battery cooling and prevent harmful hot spots.

Our cold plates perform a structural function – ideal for applications such as commercial vehicles and trains.

A flux-free vacuum brazing process ensures that the cooling plates remain extremely resistant and durable.

Minimal deformation of the plates reduces mechanical stress on sensitive battery components.

CO₂-reduced production and the use of recycled materials actively contribute to sustainability.

| Feature | Details |

| Maximum dimensions | 800 mm x 2600 mm |

| Plate thickness | ≥ 5 mm |

| Production variants | Fully machined or deep-drawn |

| Production process | Vacuum brazing (without flux/acid) |

| Surface | Various coatings available |

| Contact surface treatment | Precision machining for optimal cell contact |

| Simulation | CFD-optimized thermal designs |