E-mobility is evolving rapidly, and with it, the demand for ultra-fast charging infrastructure is growing. High-power charging is key to making electric vehicles practical for everyday use. However, the higher the charging power, the greater the thermal challenge—and the need for efficient cooling.

Miba Cooling is setting new standards in high-power charging system cooling with its vacuum-brazed water-cooled heat sinks.

High Power Charging (HPC) refers to ultra-fast charging of electric vehicles, typically delivering power from around 350 kilowatts up to several megawatts.

The goal is to significantly reduce charging times—ideally to a level comparable to conventional refueling. This is especially critical for commercial vehicles, buses, and logistics fleets, where quick recharging is essential for cost-effective operations.

To deliver such high charging power safely and efficiently, robust direct current (DC) architectures are used.

The first systems delivering over 800 kW are already under development. In the long term, megawatt charging will play a key role, particularly for electric trucks and heavy-duty commercial vehicles.

However, these extreme power levels require more than just advanced power electronics — they demand sophisticated thermal management strategies. Efficient cooling of high-power charging systems is therefore a crucial factor.

The higher the charging power, the more heat is generated - especially within the power electronics. If this heat isn’t efficiently dissipated, it can lead to serious issues:

Power Loss: Overheated components operate less efficiently, directly impacting charging times

Wear and Tear: Continuous thermal stress significantly reduces the lifespan of key components

Safety Risks: Excessive temperatures can cause malfunctions or even complete system failure

Charging Power Limitations: Without adequate cooling, the system must reduce charging power to prevent damage

Efficient thermal management is therefore critical to ensure the performance, reliability, and safety of high-power charging systems.

Traditional air cooling is no longer sufficient for these demanding applications. It tends to be noisy, maintenance-intensive, and quickly reaches its limits in compact designs.

Miba Cooling addresses this challenge with vacuum-brazed water-cooled heat sinks specifically engineered for high-power charging environments. This technology provides the foundation for fast charging systems that are durable, low-maintenance, and consistently high-performing.

Liquid cooling is the most effective solution for enabling charging capacities in the range of several hundred kilowatts or more to remain stable over the long term. Water cooling in particular offers high thermal conductivity and can reliably dissipate large amounts of heat even in small spaces.

Compared to air cooling, cooling high-power charging solutions with water offers the following advantages:

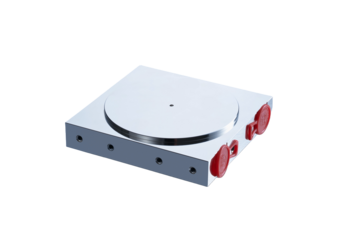

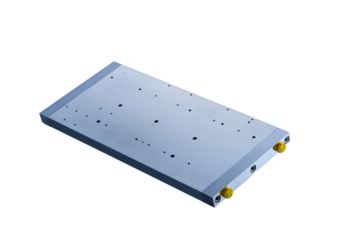

Vacuum-brazed water heat sinks have proven particularly effective. These consist of a base plate—in which the cooling structure is milled—and a cover plate, which are permanently and stress-free connected under vacuum.

This results in high-performance cooling structures with optimized heat transfer and robust construction.

Miba Cooling manufactures such heat sinks precisely according to the requirements of modern charging infrastructure. The solution is modularly adaptable and optimized for continuous operation.

Today’s charging infrastructure demands go far beyond just delivering high power. Operators and OEMs expect systems that are flexible to integrate, low-maintenance, and highly efficient. Liquid-cooled systems are specifically designed to meet these expectations.

High-power charging systems with water cooling integrate seamlessly into modern charging architectures. These cooling solutions enable:

DC distribution architecture for fast and centralized charging

Compatibility with CCS and CHAdeMO, allowing support for a wide range of vehicle types

Easy integration of energy storage and photovoltaic systems, helping to smooth load peaks and reduce energy costs

Modular system design, enabling scalable performance based on site-specific needs

Modern charging units combine multiple key advantages in a compact enclosure. Their rugged construction with a durable steel frame ensures longevity and resilience—even in demanding environments. At the same time, the maintenance-friendly design allows for quick and easy service operations. Inside, high-performance silicon carbide (SiC) electronics deliver maximum energy efficiency.

Miba Cooling designs and manufactures high-quality thermal solutions for the charging infrastructure of the future. At the core is vacuum-brazed water cooling—a highly compact and efficient technology specifically tailored for cooling high-power charging systems.

Miba Cooling’s heat sinks are:

Extremely durable, designed for long-term outdoor use

Modular and adaptable to various applications such as rectifiers, connectors, and cables

Low-maintenance and reliable, even under continuous high loads

With decades of experience in thermal management, Miba Cooling delivers the right solution for every ultra-fast charging application. From concept development to full-scale production, the company serves as a trusted engineering partner every step of the way.

High-power charging is a cornerstone of future mobility. For charging infrastructures delivering 350 kilowatts and beyond to operate reliably, intelligent thermal management is essential.

Miba Cooling’s vacuum-brazed water-cooled heat sinks deliver stability exactly where it matters most—ensuring safe, efficient, and long-lasting performance in high-power charging systems

Miba Cooling is your partner for customized thermal solutions tailored to high-power charging systems. Let us support you in developing efficient, reliable, and future-ready cooling for your HPC infrastructure.