The conventional method of transmitting electrical energy over long distances using alternating current results in significant losses. High Voltage Direct Current transmission, or HVDC for short, enables energy to be transported much more efficiently. This is achieved by transmitting energy with a high DC voltage with minimal losses.

Liquid cooled cold plates are ideal for cooling power electronics in HVDC applications.

In this blog article, you will learn why this is, what liquid cooled cold plates exactly are, and what advantages they have.

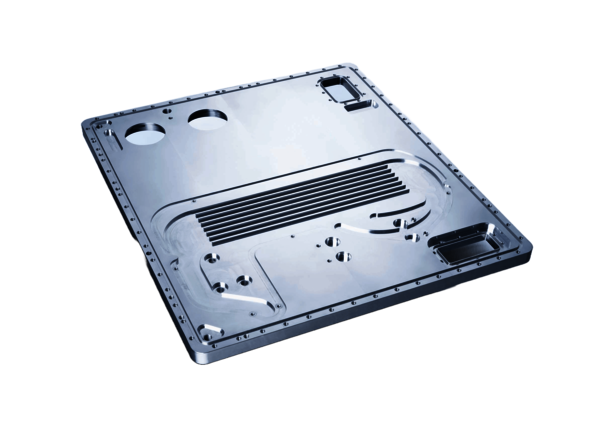

A liquid cooled cold plate is part of a cooling system, that effectively cools power electronics components as IGBT’s or thyristors. Inside the liquid cooled cold plate there is a cooling structure, through which flows a coolant consisting of deionized water or a mixture of water and glycol.

Its main task is to keep the temperature of the electronic components below a critical level. If this does not work, the electronic components may become damaged and fail. When designing the cooling structure, vacuum solder connection technology offers the most options for adapting the cooling structure to the electronic component.

With DAU Cooling, this cooling structure configuration is

That is how we ensure that the lifespan of power electronics is significantly extended.

Converter stations in HVDC systems convert alternating current into constant direct current. The aim is to transport it over long distances and with as little loss as possible. This property makes High Voltage Direct Current transmission (HVDC) particularly suitable for transmitting energy from renewable energy sources. One example of an application is the transport of electricity from offshore wind farms in the North Sea to consumers in southern Germany.

During operation, the electronics that perform the conversion to direct current generate a great deal of heat, which must be dissipated using optimal cooling. Inadequate heat dissipation leads to a rapid rise in temperature in the power electronics. This results in damage or even destruction of the components.

The result is costly downtime, expensive repairs, and high operating costs. In addition, energy consumption increases if devices or components overheat.

If the power electronics in these stations are effectively cooled using liquid cooled cold plates, technical functionality is guaranteed over the lifetime of the components.

Efficient heat dissipation through liquid cooled cold plates enables electronic components to function within an ideal temperature range. This results in a significant reduction in operating costs, which is especially important in energy-intensive industries. Ultimately, profitability is improved.

The precise control of the temperature achieved with liquid cooled cold plates extends maintenance intervals. This is because overheating is avoided, and consequently premature wear is prevented. This means less maintenance and repairs are needed.

The result: less downtime and lower maintenance costs. At the same time, network operators benefit from the components having a longer service life. This results in improved productivity and reliable availability.

A longer useful lifetime for devices and components reduces the need for their disposal. This leads to a reduction in electronic waste.

In addition, we focus on sustainable processes when manufacturing liquid cooled cold plates. This includes

Overall, this saves resources in various areas, from energy to materials.

Liquid cooled cold plates play a crucial role in High Voltage Direct Current (HVDC) transmission applications. They efficiently dissipate heat from electronic components. Their cooling effect prevents damage to the power electronics, avoiding costly failures and repairs that would otherwise reduce the service life of the systems.

They also reduce operating costs and improve profitability, especially in energy-intensive industries.

Would you like to learn more about liquid cooled cold plates? Do you have any questions about how you can benefit from this technology in your industry?

Our service experts are here to help you.